anodize seal test chromate|anodic oxide seals : manufacturing NAVAIR’s trivalent chromium treatment has also been used to replace high and mid temperature anodize seals. It has proven to be environmentally friendly and efficient anodize seal without any hazardous . WEB14 de dez. de 2021 · Carlinhos Maia, de 30 anos, deixou escapar nesta terça-feira (14) um vídeo de suas partes íntimas. Ao postar stories no banho, o humorista publicou um .

{plog:ftitle_list}

Resultado da BMF (or Black Mafia Family) is an American crime drama television series created by Randy Huggins, which follows the Black Mafia Family, a drug trafficking and money .

7075-T6. The solution presented here consists of a trivalent chromium conversion followed by a post-treatment, designed to be rigorously similar to hexavalent chromium processes in terms .It includes a study of extended protection additive in a trivalent chromium process bath for corrosion performance evaluation on aluminum as well as its use as anodic seal. Chromate .

conversation coating and anodize seal processes factors which may be of critical to coating system stack-up. Those process factors include: - Trivalent chromium coating /anodize seal .One alterna-tive is trivalent chromium, which may not be as effective as hexavalent chromium, though it is less environmentally damaging. This paper will describe a new trivalent chromium . NAVAIR’s trivalent chromium treatment has also been used to replace high and mid temperature anodize seals. It has proven to be environmentally friendly and efficient anodize seal without any hazardous . Chromate coatings provide an excellent nonporous bonding surface for all paints that have good molecular adhesion. A summary of general uses for chromate conversion .

trivalent chromium anodic seal

Hexavalent chromium (Cr 6+) containing chromic acid anodization (CAA) 1 and chromate conversion coating (CCC) 2, 3, 4 have been the central processes in the surface .Chromate conversion coating is distinct from chromic acid anodizing (see Figure 1), because anodizing involves an electrochemical method whereby the metal surface is converted into an . Anodizing has several clear benefits over other aluminum finishes. Combined with a quality control program that incorporates common test methods these benefits can be maximized. The most common of these test methods .

A. 1. A dichromate seal for conventional Type II anodizing on aluminum would be 100 gm/Liter (13.333 avoir. oz./gal) of either sodium or potassium dichromate, 200-212 °F, pH 5.0-6.0 adjusted with Sodium or Potassium Hydroxide and acetic acid ⇦ this on eBay or Amazon [affil links]. 2. This paper provides processors with an extensive troubleshooting tool when conversion coating failures are encountered. Common issues addressed are: uneven coatings resulting in streaks or blotches; dull brown . Schematic illustration of the three ways in which aluminum cations coordinate with oxygen anions in the porous anodized aluminum oxide layer (octahedral coordination is reported [78,87] to be anions in the porous anodized aluminum oxide layer (octahedral coordination is reported [78,87] to enhanced by sealing at the expense of tetrahedral . Hard Coat anodizing provides high wear resistance, typically scoring a weight loss of 1.0-1.5 mg/1000 cycles in the ASTM D4060 abrasion resistance test. Regular anodizing offers moderate wear resistance, scoring a weight loss of about 20-35 mg/1000 cycles in the same test. Corrosion Resistance

- Trivalent chromium coating /anodize seal bath concentration, bath temperature, dwell time critical to avoiding surface powdering. - Post anodize seal or coating step (e.g. use hot water post-treatment), pretreatment ageing and re-activation surface prior to primer spray application.Test Methods For Type II Anodized Aluminum. Oxide Coating Thickness. ASTM B 244-97 (2002) ASTM B 487-85 (2007) Min Thickness. Class I. 18 Microns (µ) Class II. . Where extreme abrasion resistance is required do not seal as some softening is encountered. Type III Anodize Thickness Guide. Alloy. Major Constituent(in) Maximum Thickness* Color .The Non-Chrome 6 Anodize Seal project was proposed and executed as a performance screening exercise of non-hex-chrome (with no nickel or cobalt) sealing solutions used for anodized aluminium, with and without paint coatings, (organic finishes, chromated and non-chromated), either developed

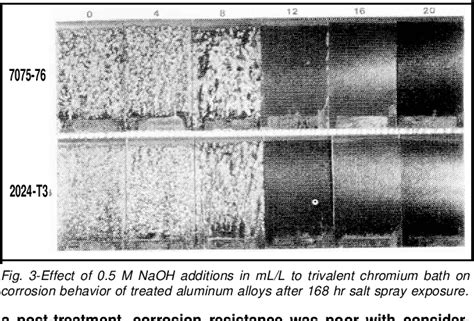

NAVAIR’s trivalent chromium treatment has also been used to replace high and mid temperature anodize seals. It has proven to be environmentally friendly and efficient anodize seal without any hazardous chemicals. . We had used addition of 25% EPA in a standard trivalent chromate bath for our test evaluation. The objective here is to study .Improved Chromic Acid Anodize Seal for Optimum Paint Adhesion Y. Moji Boeing Materials Technology Boeing Commercial Airplane Co. Seattle, WA ABSTRACT A new anodize sealing process using a dilute solution of chromic acid and metal Chromates in de i on i zed water has been developed. Use of this process to seal chromic acid anodize layers gives .

It will require extra pieces of customer metal for destructive testing. Test results may add 3 or 4 weeks to obtain certifications. . Alloys 2024 and many aircraft alloys require a dichromate seal to meet the performance specifications of MIL 8625 Type 2, Class 1. . Anodized Aluminum Spacer Bars; Aluminum Sheet for Lighting Products;

L-1, pH 6.0-7.5, 90-95 ºC, 30 min. Let’s get into an overview of the Alodine finish/chem film/chromate conversion coating, covering its types, classes, standards, processes, and comparison with anodizing, etc. Junying is capable of providing Chromate conversion coating surface finishing service for your aluminum machined parts or other components.Aluminum Anodizing: Introduction & FAQs. Everything you need to know. Type 1, type 2, type 3, Hardcoating. Dyeing & sealing, Stripping, redoing, specs, etc. . Consult the latest version of Mil-A-8625 for a discussion of type IC "non-chromate" coatings and type IIB "thin sulfuric" coatings. But it goes without saying that the OEM specifies the .

A chromate conversion coating is a type of conversion coating . friendly and efficient anodize seal with no hazardous chemicals. The TCP is QPL (Qualified Product List) approved from the United . which examined test results of various aluminum alloys treated with different process cycles. Various times, temperatures and . Conversion coatings imbue metals with special properties, such as corrosion and wear resistance, paint receptivity, or aesthetic effects. These treatments are generally straightforward to implement and open up a plethora . Yes, there are other seals for anodized aluminum, including simple hot water or nickel acetate, which are not quite as corrosion resistant as dichromate, but can still effectively seal the anodizing without leaving toxic dichromate on the parts. Regards, Ted Mooney, P.E. RET Striving to live Aloha finishing.com - Pine Beach, New Jersey July 2015The authoritative public forum for Metal Finishing since 1989 -----Sealing Process for Hard Anodize MIL-A-8625. Q. MIL-A-8625 / MIL-PRF-8625 [on DLA] Type III, Class 2 After Humidity test (Five 48-hour cycles), the black dye appeared to .

Chromate Conversion Coatings for Aluminum (Chem Film) per MIL-DTL-5541. What is Alodine ®?Also known as chem film or chemfilm, Alodine ® is a chromate conversion coating that protects aluminum and other metals from corrosion. Related products include Iridite ®, TCP-HF, Bonderite ®, and Chromicoat ®.The process of applying a chromate conversion coating . In fact, to be honest, if you're immersing the entire anodized part into the chem film bath, I'd be fairly certain that the chromating bath would eat into the anodize seal layer and disrupt it to the point where the anodize will no longer pass 336 hour salt spray. Meanwhile, aluminum anodizing is usually thicker, with about tens of microns of impact on the final dimensions of metal parts. The coating thickness level ranges from 0.00001 (in Type 1 anodizing) to 0.001 (in Type III anodizing). Functionality. Alodine coatings and anodizing have similar applications since they offer corrosion protection. tetwin11-MIL-C-5541, cl.3 alodine is intended for electrical bonding of faying aluminum surfaces. But it is also common practice to seal the joints after assembly, using primer/paint or sealing compounds, to prevent intrusion of moisture.

alloy surface has traditionally been a chromate conversion coating (CCC)4–6. However, hexavalent chromium used in the CCC coatings is considered a . conversion and for sealing after anodizing. The conversion layer can be created by immersion or by . by a cross-cut test according to the specifications ISO 2409 and ASTM D3330 in wet and dry . FUTURE WORK Having established the test methods and acceptance criteria for replacing sodium dichromate sealers, as well as available candidates for testing, the effort will focus on testing and data evaluation. It is anticipated that this work will identifY a candidate that can meet the needs ofOO-ALC with respect to an anodizing seal.

A. Chromate first all over, mask the chromate area, strip and anodize. The 40 volt chromic anodizing attacks the edge of the maskant more than the 20 volt anodize. Use the best quality maskant. Do not use lead tape. Use plastic tape, well mashed down. There is one maskant leader in our industry but I cannot name him here. Robert H ProbertSeal the pores. After anodizing, you have to seal the microscopic pores on the surface of the part to prevent further corrosion and improve performance. Without sealing the pores, anodized parts may feel sticky to the touch. As well, open pores can collect dirt, contaminants and stains. These are three common processes for sealing pores:

nickel acetate vs anodize

To seal the porous surface created during the anodizing process and provide a uniform surface, the part needs to go through a final step where it is immersed in a nickel acetate solution. . (0.5 to 2.5 microns) on aluminum parts. Chromate anodizing produces the thinnest coating and the least color absorption of the three main anodizing types .

chromium anodized aluminum seal

chromate conversion coating

how to measure carotid intima media thickness

Título Título ou resumo errado ou episódio fora de ordem Vídeo Desfocado, cortado ou .

anodize seal test chromate|anodic oxide seals